Design and modelling of a low-cost aerosol particle counting device

The measurement of atmospheric airborne particles is important for contributing to human health and assessing a number of manufacturing processes. Inexpensive sensors exist for measuring larger particles (> 1000 nm), but those for ultrafine particles (<300 nm) remain too expensive (>£10,000) for use in sensor networks, yet these represent about 90% of the number of typical airborne particles in urban settings. These include vehicle emissions within 10-100 nm and viruses around 100 nm.

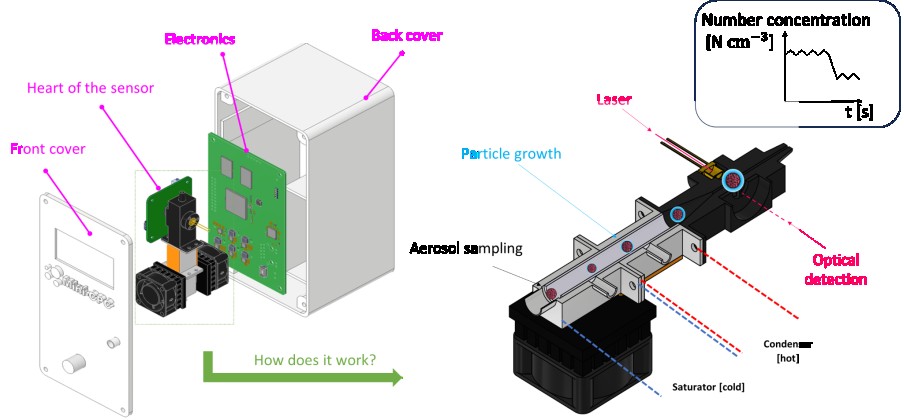

This project will work with Cambridge university startup Aetosense who are looking to bridge this gap with their low-cost ultrafine sensor. A prototype sensor for quantitative nanoparticle measurements has been built and tested. The sensor is based on using water vapour to grow individual particles into larger droplets, and using a beam of laser light to scatter off the droplets along a flow column. Water vapour is delivered using a saturated wick at a controlled heating rate, followed by condensation on the particles in a colder section. Some preliminary model has been undertaken, but further studies are required to optimise the overall approach and help invert the signal to provide particle number concentrations.

Left: exploded view of existing prototype. Right: outline of flow path of particles and layout of condensation pathway and optical line of sight.

Objectives:

- Produce a quantitative model of how particles grow by water condensation in the system

- Couple the model to modelling of the optical extinction of the signal

- Compare the model results and experimental data

- Indicate directions for improving the overall power and water consumption rate of the device.

Expected Tasks

- Basic CFD modelling: Produce a CFD model of the unit based on previous modelling using COMSOL, by adding a porous flow model for the wicking medium, and produce a coupled heat and mass transfer analysis of the droplet growth, which will be initiated by a point-based Lagrangian model. An extension of the model would be to add particle diffusion to the Lagrangian (or Eulerian) model of particle growth. Validation will be produced against a state-of-the art condensation particle counting (CPC) device

- Optical modelling: The output of the CFD simulations of particle extinction along the line of sight of the laser beam. Validation will be provided against the signal obtained in the device prototype.

- Optimisation: if time allows, recommendations from the model simulations will be made to reduce water and power consumption.

Requirements:

- interest in CFD simulations

- familiarity and interest with programming languages (python, matlab) sufficient to extract data for visualisation

- interest in heat and mass transfer (ok to learn on the job by looking at 3A6 notes)