|

|

|||

|

Department of Engineering |

| University of Cambridge > Engineering Department > Photo competition |

|

First prize Dr Steve Hoath 'Tails from the nozzle bank ' This was taken with a Nikon D70 with a Navitar zoom macro lens and a very short flash duration (20 ns) light source. This image was taken during a series of experiments at the Department's, Inkjet Research Centre investigating the performance of inkjet printers. Click on image to see a larger version |

|

| Second prizeLaura Harrison 'untitled' Laura's photo is of prototypes of elastic chain-link designs. These designs are part of her fourth year project within the Production Processes group, investigating the potential for using 'Selective Laser Sintering' processes to produce textile structures, as part of wider research to establish new garment manufacturing techniques. Click on image to see a larger version |

||

|

Third prizeDr Jack Luo and Dr Yong Qing Fu 'Nanohand and its captured ball' Dr Jack Luo and Dr Yong Qing Fu have developed this microgripper to hold biological samples. The photo was taken using a scanning electron microscope and shows a ball only ~65µm across captured in the cage of the microgripper. Click on image to see a larger version |

|

Other entries |

||

|

Adam Ardron Solar Wind The image shows the wind turbine used for my fourth year project. The title was chosen because the sunlight almost appears to be directly driving the turbine. Click on image to see a larger version |

|

|

Nikos Bamiedakis 'Polymer Spiral Waveguide' The photo was taken when He-Ne light was coupled into a polymer spiral waveguide. Optical fibres were used at both ends. The shape of the waveguide can be easily seen as well as the scattered light at the input/output due to coupling losses and at the middle of the spiral due to bending losses (acute s-bend). Click on image to see a larger version |

|

| Adam Blacklay 'Functional Beauty' The canopy of the Sony building in Berlin. Click on image to see a larger version |

||

| Louise Bloom Empty vendor - Sunday department vending machine Click on image to see a larger version |

||

| Andrew Boyce Failure! This photo was taken during a structural design project. Click on image to see a larger version |

||

| Tore Butlin 'Still Life' An image of traditional engineering building blocks - everyday objects to engineers in the same way that teapots and fruit are to an artist. Also featured is a research-specific element: the hexagonal honeycomb backdrop for lightweight stiff structures. (Only colour enhancements and minor blemish correction have been applied.) Click on image to see a larger version |

||

|

Mirco Cantoro Dreamtronics The image shows an artistic rendering of a secondary-electron image of a carbon nanotube-based array of field effect transistors, fabricated by multiple steps of electron-beam lithography. The thin carbon nanotube strip located in the middle of the device is contacted by multiple metal finger pairs, running back to larger bond pads. Click on image to see a larger version |

|

|

Helen Cavill Foundryman I worked in an iron foundry for several years before starting my degree at Cambridge. The photo shows one of the workers scraping the launder of the furnace to keep the molten iron flowing. The foundry process is wonderfully dramatic to watch very few people know a lot about it. I really enjoyed working there! Click on image to see a larger version |

|

|

Alan Colli 'Nanodragons like heat' Field-emission scanning electron microscope image of branched CdSe nanostructures grown at 500șC. Such 3D nucleation regime give rise to very peculiar shapes, and may lead to fantastic visual interpolations. The image has been enhanced using Corel Photo Paint. Full width: 3”m. Click on image to see a larger version |

|

| Neil D'Souza-Mathew 'Air Compressor in Action' Picture of a rural Air Compressor, filling our tyres at a roadside garage en route to the Himalayas. This image was taken by myself using a digital camera and has not been enhanced in any way. Click on image to see a larger version |

||

| Sam Davies Leaf structure Natural structures are far more advanced than anything that we can currently produce. The veins in this leaf are not only the frame that supports the leaf cells, but also a highly optimised delivery network providing nutrients and water that allow photosynthesis to take place. Click on image to see a larger version |

||

|

Colm Durkan 'Molecular heights' Islands of molecules on a gold surface, which itself has a few steps (they are the lines meandering across the image). The image area is 200 nm x 200 nm. Click on image to see a larger version |

|

|

Colm Durkan 'Nanocapacitors' Atomic force microscope image of capacitors (made by electron-beam lithography) on piezoelectric thin film. Image size = 2 mm x 1.5 mm. Click on image to see a larger version |

|

|

Alison Ford Crystal Growth A micrograph of crystallising chiral dopant. Click on image to see a larger version |

|

|

Laurence Hargreaves Has anyone told the Engineers? Taken early morning on a dam construction site in Iran, on an engineering placement this summer. I love how everyone is waiting for someone else to do something! No-one was hurt in this incident. Click on image to see a larger version |

|

|

Steve Hoath 'A moment of reflection ' This was taken with a Nikon D70 with a Navitar zoom macro lens and a very short flash duration (20 ns) light source. This image was taken during a series of experiments at the Cambridge Engineering Department, Inkjet Research Centre investigating the performance of inkjet printers. It shows drops from an inkjet print head having just hit or just about to hit a glass surface in which they are reflected. Before hitting the surface the drop heads are 50 microns across and the tails are less than 10 microns wide (10 times thinner than a human hair). Although very small the drops are moving at around 6 m/s hence the need for a very short flash to freeze the motion. Click on image to see a larger version |

|

|

George Jones 'Working with Robots' "My 4th year project used the facilities of the automation laboratory to research into the up and coming area of Radio Frequency Identification (RFID). Often this involved using the robots, however, sometimes, they just liked to pose!" Click on image to see a larger version |

|

|

Faye Karababa Traditional antiseismic structural system This picture shows a traditional antiseimic structural system found in Lefkada Island, off the West coast of Greece, dating possibly 250 years ago. On the ground floor, stone masonry is designed as the primary support system, which may fail during an earthquake dissipating in this way some of the earthquakes energy. Click on image to see a larger version |

|

| Priti Parikh 'Data collection' This picture shows myself (in the pink top) collecting data in the slum settlement of Sanjaynagar, Ahmedabad city, India. The complexity of interactions, colours and dicussions can enrich engineering research and contribute to a better understanding of human needs. Click on image to see a larger version |

||

| Priti Parikh 'Goodbye' This picture shows myself (in the pink top) saying goodbye to children in Hansol slum settlement. The settlement is deprived of basic water and sanitation amenities and peole live there in extreme hardships. These are the places where engineers really need to go and work! But it is still very encouraging to see smiles on the faces of children. Click on image to see a larger version |

||

|

Amanda Pyatt Untitled Plants being grown by Michael Habottle, Ph.D researcher for MRI imaging to detect whether contaminants are being taken up into the plant from the soil. Click on image to see a larger version |

|

|

Giles Richardson 'Predicted ground plane temperature contours during aircraft landing' This is a jpeg image that has been generated using Fieldview CFD post-processing package, based on an unsteady RANS flow solution. Acknowlegments: Professor Bill Dawes and Professor Mark Savill. Click on image to see a larger version |

|

|

Keith Seffen A morphing shell, by dimple inversion A thin sheet of copper alloy is first dimpled using a hammer and punch, to render a golf-ball-like surface. Each dimple can then be inverted by hand back and forth, and depending on the orientation of clusters of dimples, the sheet is either cylindrical, partially curved, or flattened. Click on image to see a larger version |

|

|

Ben Sheppard 'In a Spin' This long exposure photograph shows an experiment used to study the flows within tornadoes and whirlpools. A tank of water, placed on a rotating table, is spun up until the water is in solid-body rotation. Particles suspended within the water are then illuminated and tracked so that the velocity field within the fluid can be determined. Click on image to see a larger version |

|

| Ben Sheppard 'In a Spin' This long exposure photograph shows an experiment used to study the flows within tornadoes and whirlpools. A tank of water, placed on a rotating table, is spun up until the water is in solid-body rotation. Particles suspended within the water are then illuminated and tracked so that the velocity field within the fluid can be determined. Click on image to see a larger version |

||

|

Dr I Thusyanthan Tsunami Wave Impact on a Sri Lankan costal house Model testing (1/25 scale) of tsunami wave impact on house, Image captured by 1000 frames per second high speed camera. Click on image to see a larger version |

|

|

Jim Woodhouse "Then we hit it with a hammer - but only a small one..." Vibration testing of a violin. A small hammer containing a force transducer strikes the violin bridge to excite vibration with a known force waveform. The resulting vibration is measured using a laser-Doppler vibrometer: the red spot on the near corner of the bridge shows where the laser beam is striking. Click on image to see a larger version |

|

|

Jim Woodhouse The "Rubio six"or acoustical research using a grant from the Royal Society. The violins were made by the luthier David Rubio, using carefully matched raw materials and embodying deliberate variations of constructional details which were controlled by vibration measurements during construction. Externally, the instruments are very similar so that it is possible to do experiments in which players are handed one instrument or another and asked to comment on their qualities, without being able to tell the difference by look or feel. Click on image to see a larger version |

|

|

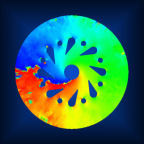

Saffron Wyse Induced Swirl In A Combustion Premixer The photo shows a steady CFD solution of the atmospheric combustion "buzz" rig in the Hopkinson Lab. The "buzz" rig contains a scale model of the Rolls-Royce Plc RB211-DLE swirl-stabilised flameholder. The photo shows the atan (y-velocity/z-velocity) within the upstream section of the swirler. The swirl vanes (wedge shapes) and fuel injectors (circular shapes) have been removed during rendering. This image has had the original grey rendered background removed, and a black/blue gradient background added instead. Click on image to see a larger version |

|

|

Saffron Wyse Reaction Progress In A Swirl-Stabilised Combustion Chamber The photo shows a steady CFD solution of the atmospheric combustion "buzz" rig in the Hopkinson Lab. The "buzz" rig contains a scale model of the Rolls-Royce Plc RB211-DLE swirl-stabilised flameholder. This photo shows the velocities in the upwards (x) direction, (blue = unburt to red = fully burnt). The transparent rendered colours denote the progress of the variable at the wall of the combustion chamber. The entrainment of a single streamline within the low-pressure recirculation zone generated by the swirling flow, until the streamline's eventual exit from the recirculation zone , and subsequently the combustion chamber. The swirler is at the bottom of the image, and the swirl vanes and fuel injectors have been removed from the image during the rendering. Click on image to see a larger version |

|

|

Matthew Zedler Simple Science: Pelton Wheels and Coils in Lesotho These turbines and coils were made by students at the Bethel Business and Community Development School in rural Lesotho as part of a demonstration. By seeing how electricity could be generated from running water, they got a much better understanding of how science and technology could be used in their everyday life. Click on image to see a larger version © Copyright notice You may copy an image from the photography competition, reproduce it, and distribute it, but only if you clearly attribute the image to the student or academic who took the photograph, state that they work in the Department of Engineering at the University of Cambridge, and acknowledge Epson's sponsorship of the competition. It would also be courteous to provide a links to www.eng.cam.ac.uk and www.epson.co.uk. We would be delighted to hear where the images have been used. Please contact marketing@eng.cam.ac.uk to let us know. |

|

Photo Competition Archives |

| All previous year's photos can be found at: www.flickr.com/photos/cambridgeuniversity-engineering 2010 | 2009 | 2008 | 2007 | 2006 | 2005 | 2004 | |

| | Search | CUED | Cambridge University | Privacy policy | |

|

© Department of Engineering at the University of Cambridge Information provided by web-editor |